Quality Management Team

Quality Policy and Philosophy

‘Only the best quality is the way to survive.’

With a strong belief, we provide satisfaction and trust to our customers through continuous improvement and the best quality.

품질경영팀

주요 협력 기관

- 한국생산기술연구원

- 대구기계부품연구원

Quality Policy

The company’s quality policy is set as follows to aim for the best quality for customer satisfaction, and we never compromise on quality.

1. Best quality 2. Increased added value 3. Continuous improvement

4. Acquire advanced technology 5. Customer satisfaction

Quality Goals

To ensure implementation of the quality policy, quality goals are established and operated.

1. Zero process defects 2. Increased productivity 3. Stabilized quality

4. Cost reduction 5. Zero customer defects

Quality Management

In order to provide stable and reliable products, we place quality control capabilities at the core. Quality control plays a key role in ensuring that we maintain the highest level of quality at every stage of our products. We are in charge of quality management (QM), quality planning (QP), and project management (PM).

Quality Control

We focus on continuously improving product quality and maximizing customer satisfaction by establishing an efficient and effective quality management system. We ensure quality by systematically carrying out activities such as production, inspection, testing, and documentation. We are also responsible for quality control (QC), quality assurance (QA), and quality improvement (QI).

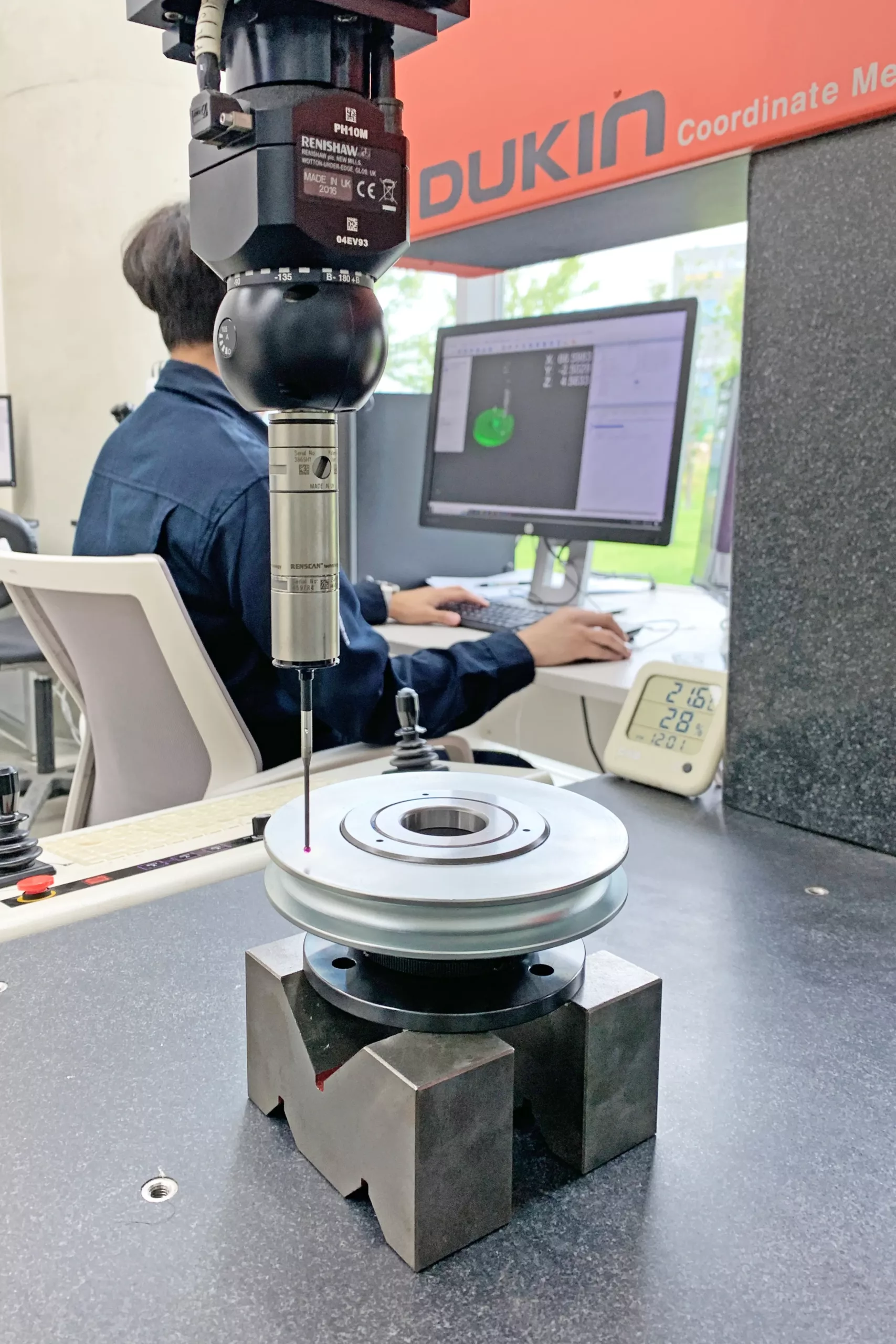

Precision measurement room

For more detailed manufacturing, we pay great attention to quality and pay a high level of attention to quality control, including having a separate measurement control room. Yeonhap System maintains strict standards for quality to always provide the best products to its customers.

Always keep clean

Periodically calibrate all measuring instruments in the measuring room

Soundproofing and dustproofing system applied

Temperature and humidity management according to standard room environmental standards

Temperature 20± 2℃ (1℃/hour), humidity 55%)

Quality Management

Yeonhap System maximizes customer satisfaction by providing the best quality and service to customers and pursues continuous growth and development.

quality system

Quality Management System | Environmental Management System Certificate

By introducing the ISO9001 quality management system, we maintain a consistent quality level throughout all operating processes. This system helps us deliver the best value to our customers and provides the foundation for continuous improvement. To satisfy our customers’ diverse quality requirements, we operate a systematic quality management process based on the internationally recognized ISO 9001 quality management system. In order to produce the highest quality products, our quality management system will continue to improve, meet the requirements of ISO9001 and ISO14001, and comply with domestic and international laws and standards during the product manufacturing process.

Possessed measuring instruments

Yeonhap System has a total of 14 types of measuring instruments for accurate product size management and various reliability tests.

| equipment name | Usage |

|---|---|

| Contact 3D measuring device | Dimension, shape, and geometric tolerance measurement |

| roundness measuring instrument | Geometric tolerance measurement (roundness, cylindricity, runout, concentricity, etc.) |

| Roughness & Shape Measuring Instrument | Shape and illuminance measurement |

| rockwell hardness tester | Surface hardness test |

| Micro Vickers Hardness Tester | Core hardness test |

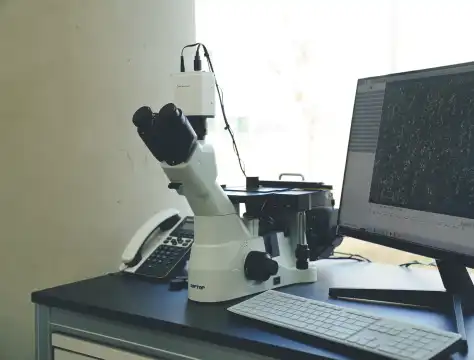

| metal microscope | metallographic examination |

| Precision specimen cutting machine | Cutting specimens for inspection |

| mounting press | Forming specimens for inspection |

| polishing machine | Polishing specimens for inspection |

| bearing clearance gauge | Bearing gap measurement |

| digital height gauge | Dimension measurement (width, height) |

| Electronic scale (0.01g) | Part weight measurement |

| Electronic scale (0.1g) | Part weight measurement |

| Mast Roller Bearing Impact Tester | Mast roller bearing impact strength test for forklifts |

3D measuring instrument – (HERO7106S)

a major role

Periodic process inspection for mass-produced products

Final inspection of finished products

Check compatibility with other products

Various GD&T tolerance analysis

Extracting information needed for product development (Reverse Engineering)

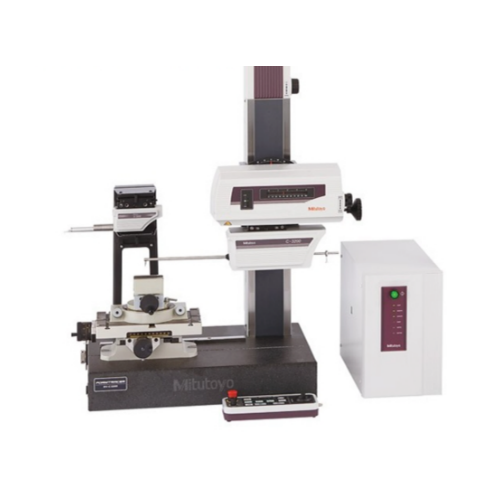

Roundness measuring instrument – (RA-2200AS)

The measuring instrument is an advanced instrument capable of measuring key quality-related indicators such as straightness, roundness, cylindricity, parallelism, perpendicularity, coaxiality, circumferential runout, and total runout, ensuring high quality standards are maintained in our manufacturing processes. It is making a great contribution to

The RA-2200AS provides outstanding accuracy and reliability, ensuring superior performance in key measurement and quality control steps during product manufacturing. Through this, we strive to confirm the true quality of our products and improve production efficiency and minimize defect rates by detecting and taking action early on potential problems that may arise during the manufacturing process.

Micro Vickers Hardness Tester

Micro Vickers hardness tester is one of the instruments used to measure the hardness of materials. This instrument measures hardness by indenting the surface of a material using a diamond pyramid-shaped indenter.

Hardness measurement: Micro Vickers hardness tester can precisely measure the hardness of materials. Hardness is an indicator of how hard a material is and indicates the degree to which the material has strength.

Diamond Pyramid Tipping: Typically, the micro Vickers test uses a diamond pyramid to apply pressure to the surface of the material. This enables precise measurements.

Automation and data analysis: Provides automated functions and data analysis capabilities to help users work efficiently. This allows you to quickly analyze measured data and interpret results.

Response to a variety of specimen sizes: Designed to measure specimens of various sizes and shapes, allowing it to flexibly respond to a variety of applications.

보유계측기

연합시스템은 제품의 정확한 치수관리와 각종 신뢰성 시험을 위해 총 14개종의 계측기를 보유하고 있습니다.

| 장비명 | 용도 |

|---|---|

| 접촉식 3차원 측정기 | 치수, 형상, 기하공차 측정 |

| 진원도 측정기 | 기하공차 측정 (진원도, 원통도, 흔들림, 동심도 등) |

| 조도 & 형상 측정기 | 형상, 조도측정 |

| 로크웰 경도 시험기 | 표면경도시험 |

| 마이크로 비커스 경도 시험기 | 심부경도시험 |

| 금속 현미경 | 금속조직검사 |

| 정밀 시편절단기 | 검사용 시편 절단 |

| 마운팅 프레스 | 검사용 시편 성형 |

| 폴리싱기 | 검사용 시편 연마 |

| 베어링 틈새 측정기 | 베어링 틈새측정 |

| 디지털 하이트 게이지 | 치수측정(폭, 높이) |

| 전자저울(0.01g) | 부품중량측정 |

| 전자저울(0.1g) | 부품중량측정 |

| Mast Roller Bearing Impact Tester | 지게차용 마스트 롤러베어링 충격강도 테스트 |

3차원측정기 – (HERO7106S)

주요역할

대량 생산 제품에 대한 주기적인 공정 검사.

완성품에 대한 최종 검사.

상대 제품과의 호환성 여부 점검.

다양한 GD&T 공차 해석.

제품 개발에 필요한 정보 추출 (역설계-Reverse Engineering)

진원도 측정기 – (RA-2200AS)

측정기는 진직도, 진원도, 원통도, 평행도, 직각도, 동축도, 원주 흔들림, 전체 흔들림 등의 핵심적인 품질 관련 지표를 측정할 수 있는 고급 기기로, 우리의 제조 프로세스에서 높은 품질 표준을 유지하는 데 큰 기여를 하고 있습니다.

RA-2200AS는 뛰어난 정확성과 신뢰성을 제공하여 제품의 제조 중 핵심적인 측정 및 품질 관리 단계에서 우수한 성과를 보장합니다. 이를 통해 우리는 제품의 진짜 품질을 확인하고, 제조 프로세스에서 발생할 수 있는 잠재적인 문제를 조기에 감지하여 조치함으로써 생산 효율성을 향상시키고 불량률을 최소화하고자 노력하고 있습니다.

마이크로 비커스 경도 시험기

마이크로 비커스 경도 시험기는 재료의 경도를 측정하는 데 사용되는 장비 중 하나입니다. 이 기기는 다이아몬드 피라미드 형태의 압입체를 사용하여 재료의 표면에 압입을 가하여 경도를 측정합니다.

- 경도 측정: 마이크로 비커스 경도 시험기는 재료의 경도를 정밀하게 측정할 수 있습니다. 경도란 재료가 얼마나 단단한지를 나타내는 지표로, 재료가 강도를 갖는 정도를 나타냅니다.

- 다이아몬드 피라미드 티핑: 일반적으로 마이크로 비커스 시험에서는 다이아몬드 피라미드를 사용하여 재료의 표면에 압력을 가합니다. 이는 정밀한 측정을 가능하게 합니다.

- 다양한 시편 크기 대응: 다양한 크기와 형태의 시편을 측정할 수 있도록 설계되어 있어 여러 응용 분야에 유연하게 대응할 수 있습니다.

자동화 및 데이터 분석: 자동화된 기능과 데이터 분석 기능을 제공하여 사용자가 효율적으로 작업할 수 있도록 지원합니다. 이를 통해 측정된 데이터를 신속하게 분석하고 결과를 해석할 수 있습니다.